- This event has passed.

Floating Farms for a Sustainable Future Seminar

August 24, 2018 @ 8:30 am - 3:00 pm

Object of Conference

The objective of the conference is to bring together experts and practitioners to share their know-how and expertise on floating farms ideas by using the sea/river/lake/reservoir as the new frontier for cultivation of food. As the world’s population migrates towards coastal areas, farm lands are under pressure for farming of livestock, fish and vegetables. Technology developed in the field of Very large Floating Structures (VLFS) is applied to take food production through a quantum leap into a new dimension. This conference presents a number of innovative ideas in floating farms that have been researched into, prototyped and put into small scale commercial production, which will be interested to government planners, food production agencies, investors, civil and structural engineers, naval architects, architects, town planners, academics and students in the offshore industry, shipyard industry, classification societies and universities.

Our Distinguished Speaker

Mr. Peter Wingerden

Mr. Peter van Wingerden is CEO and founder of Beladon, international leading company on building on water. Beladon design, engineer and develop floating concepts on rivers, ports, lakes and sea. Beladon started 7 years ago and is based in The Netherlands (www.beladon.com). Peter started the first 5 years of his career at General Electric (https://www.ge.com/benelux/en ), an American multinational conglomerate. After GE he became District Manager for 2 years at Alstom (http://www.alstom.com/about-us/), a global leader in power generation and transmission. He moved from there to lead the Industrial department of one of the divisions of Hollandsche Beton Group for 4 years. The group which offers construction services in Europe is headquartered in Netherlands (https://www.bam.com/en).

Mr. Peter van Wingerden is CEO and founder of Beladon, international leading company on building on water. Beladon design, engineer and develop floating concepts on rivers, ports, lakes and sea. Beladon started 7 years ago and is based in The Netherlands (www.beladon.com). Peter started the first 5 years of his career at General Electric (https://www.ge.com/benelux/en ), an American multinational conglomerate. After GE he became District Manager for 2 years at Alstom (http://www.alstom.com/about-us/), a global leader in power generation and transmission. He moved from there to lead the Industrial department of one of the divisions of Hollandsche Beton Group for 4 years. The group which offers construction services in Europe is headquartered in Netherlands (https://www.bam.com/en).

Mr. Leow Ban Tat

Mr. Leow Ban Tat has more than 38 years of experience in the marine and offshore industry. Founder & Managing Director of AME2, a consultancy & infrastructure design company. Also provides strategic marketing, project, business development services for offshore companies & shipyard development. Inventor of LIFT-DOC® Lift-Dock and its various applications which include NOAHs Eco-Ark® (CCFT) Closed Containment Floating Fish Farm and Lift-Dock Eco-Farming Establishment (LD-EFE). He is a fellow member of the Society of the Naval Architect & Marine Engineers, Singapore (FSNAMES) and member of the Singapore Floating Structure Society. Formerly from Keppel Shipyard, Keppel FELS Brazil, ASL Shipyard and Pax Ocean Marine and Offshore. He holds an MBA from Monash University, a First Class Marine Engineering Certificate of Competency from Newcastle-upon-Tyne, UK, & Diploma (Merit) in Marine Engineering, Singapore Polytechnic. Currently is the independent director of Penguin International Ltd. He plays significant role in our National Defense as MAJ(NS) serving as Chief Engineering Officer with Republic of Singapore Navy.

Assistant Professor Dr. Shinji Sato

Dr. Shinji Sato has a doctorate in engineering/Architect and is currently the Assistant Professor in the Department of Oceanic Architecture and Engineering, College of Science and Technology, Nihon University (https://www.cst.nihon-u.ac.jp/department/ocean/). Dr. Sato is the committee in the General Foundation Ocean Environment Creation Organization Engineering, which is a a research organization established with the aim of developing a new industry in the ocean using the marine platform. Dr. Shinji Sato leads a research project in conceptualizing an industrialization model in the marine environment and summarizing it into architectural design. As a consignment project from the Ministry of Economy, Trade and Industry in 2012, a feasibility study was conducted on the technological possibilities of CO2 fixation by effective technology utilization in the ocean by using algae and offshore platform system.

Mr Morten Lund Hoffmann

Mr Hoffmann is managing Multiconsult Asia Pte Ltd, a subsidiary of the Norwegian Engineering and Consultancy company Multiconsult. Multiconsult Asia Pte Ltd has offices in Singapore and Abu Dhabi. Mr Hoffmann holds a Master’s Degree in Engineering Management from RMIT University in Melbourne. He has held various project management positions in Multiconsult since 2002. His project portfolio includes some of Norway’s largest and most complex oil and gas and infrastructure projects. His project experience spans from the early engineering phases and throughout the detail engineering and construction phases. Also his project portfolio includes similar international projects such as the Jurong Rock Caverns project in Singapore. Morten has also managed various departments in Multiconsult, responsible for the company’s project management and control personnel and methodology, and the project decision gate and execution model and 3D/BIM strategy.

Mr Gary Wong

Mr Gary Wong is an Offshore Engineer with Keppel Offshore & Marine’s Deepwater Technology Group for the past 5 years. In the recent two years, he has been developing concepts on repurposing offshore technology for near shore solutions, several of which are currently in the prototype phase. Growing up near the coast and on a fish farm and under the influence of an Urban Town Planner and Naval Architect, he pursued an education with a BEng (Hons) Offshore Engineering from Newcastle-upon-Tyne and Singapore Institute of Technology and a Diploma in Civil Engineering and Management from Singapore Polytechnic.

Conference Program

| 0830 to 0930 | Registration |

| 0930 to 0945 | Welcome, President’s Address |

| 0945 to 1045 | Lecture 1 – FARMING ON WATER

by Mr. Peter van Wingerden, CEO and Founder of Beladon

With land as a major constraint for farming, cities could also explore floating farms on water bodies such as reservoirs and sea space. This possibility is being translated into reality in Netherlands where Beladon, a Dutch company, has designed a closed-loop modular farming platform that can float on any water body. The platform is made up of individual units which can be scaled by a factor of two to five, and units can be connected with one another to form a mega floating farm. These can be reconfigured to suit specific farming and spatial requirements. Beladon is utilising this concept to pilot the world’s first floating dairy farm in Rotterdam, Netherlands. Currently under construction, the three-storey, 1,000 square metres floating dairy farm will be able to accommodate 40 cows on the top floor and produce approximately 800 litres of milk daily. The dairy processing, feed production and manure storage will be located on the two lower floors. This floating farm’s closed-looped system will integrate water supply and treatment, energy generation, waste processing, and feed production. This dairy farm is part of Rotterdam’s planned floating farm strip that could potentially expand to include a chicken, goat, and vegetable farm

|

| 1045 to 1145 | Lecture 2 – SUSTAINABLE LIFT-DOC® ECO-FARMING ESTABLISHMENT

by Mr. Leow Ban Tat, Founder & Managing Director of AME2

Worldwide, aquaculture is a booming business as wild catch is fast diminishing while the fish consumption will increase by 20%. In 2016, about 47% of fish are farmed and by 2030 with 60% aquaculture production and most will be sea cultivation (FA0 2018). Over 88% of this increase in aquaculture production will originate from the Asian region (FA0 2018). This growth potential provides opportunities for Singapore to be the Centre of Excellence for Aquaculture. AME2 has developed an innovative and disruptive technology, we called it, Novel Offshore Advanced Hull system (NOAHs) Eco-Ark®, a closed containment flow through (EA-CCFT). It is a sustainable high density floating fish farm. It incorporates game-changing technology, which will set the standard for the global aquaculture’s food-fish production. Eco-Ark® is cost effective and has greater efficiency in (a) sea space optimization, (b) energy utilization, (c) human resource utilization, and (d) environmental management. In summary, it can produce higher yields in a smaller footprint, use less energy and eco-friendly compared to any conventional sea fish farming methodology available today. Eco-Ark®’ s NOAHs hull can be build of varying materials, not just steel or concrete. Also designed & engineered to be unmanned and withstand harsh environments in deeper sea. This makes Eco-Ark® farm deployable in coastal and deep sea farming site.

|

| 1145 to 1300 | Lunch |

| 1300 to 1400 | Lecture 4 – PROPOSAL OF COMPOSITE PLANT FACTORY BY UTILIZING MARINE PLATFORM

by Assistant Professor Dr. Shinji Sato, Nihon University

In this paper, by using “aquaculture possibility: algae energy / useful substance extraction” and “algae marine biomass production system: industrialization using algae marine biomass” by using aquaculture technology making use of regional characteristics We propose a new regional environment recycling type of industry. It is the most important point from the viewpoint of technology development to form “a community symbiosis recycling smart community aiming at marine environment creation cities” by making full use of the features and advantages of coastal areas spreading throughout Japan, especially local cities. In this paper, we will introduce a case study conducted in a corner of the Sakaide City Industrial Park of Sakaide City, Kagawa Prefecture facing the Seto Inland Sea, in order to make full use of the benefits of the ocean platform. In this project, we propose to use a fully closed plant factory or algae cultivation factory not as a single unit, but by laminating it and using it in combination. The concept of the basic configuration of this floating type complex plant plant is that the energy collecting device, artificial light plant plant and algae cultivating factory with different functions are collectively housed in a floating type marine platform, and mutual interference So that they do not overlap each other. If it is on land, these factories are to be built in separate buildings on a large site, but with the aim of trying to obtain efficiency and synergistic effect by integrating this factory and integrating the entire system vertically is there.

|

| 1400 to 1445 | Lecture 4 – DESIGN AND ENGINEERING OF FLOATING STRUCTURES IN NORWAY

by Mr. Morten Lund Hoffmann, Managing Director of Multiconsult Asia Floating structures have proven to be both costs efficient and safe for a number of different purposes. The Norwegian offshore oil and gas industry has successfully developed floating structures for the harsh Norwegian seas for decades. These solutions comprise various types of purposed design concepts, from traditional catenary moored floaters, semi-submersible platforms, to more complex tension leg and Spar platforms. The superstructures include both steel and concrete solutions. These offshore oil and gas technologies have in recent years been applied to developments of floating wind turbines and fish farms, both inshore and offshore. Also, the large Norwegian fjords impose challenges for infrastructure crossings where the water depths restrict traditional bridge solutions and the use of rock tunneling solutions. Recent developments comprise floating bridge solutions with water depths up to 500 m and crossing lengths of 4-5 km. The design basis has proven to be more decisive for the design of floating structures. This includes a range of parameters, including physical environment, bathymetry and ground conditions. Since the 1970’s, Multiconsult has provided innovative technology and project management expertise in the design and engineering of a number of complex floating solutions, from design basis, early design, geotechnical subsea foundations and anchoring, to the structural design of concrete and steel. These structures are located at various places around the world. Multiconsult has also developed a number of numerical engineering tools that are being utilized in developing such floating structures.

|

| 1445 to 1530 | Lecture 5 – REPURPOSING OFFSHORE TECHNOLOGY TO UNLOCK THE POTENTIALS OF SEA SPACE

by Mr. Gary Wong, Offshore Engineer of Keppel Offshore and Marine (DTG) We seek urban solutions to overcome limitations in space and resources associated with expanding cities and higher concentrations of populations. The regions at the forefront are coastal cities and island nations. Global warming has also contributed to these challenges by introducing a dynamic geography – rising tides, less predictable and more intense weather and rising temperatures where changes to the physical landscape are shaped through actions of others. A recognized strategy has been to develop and expand the coast line through land reclamation. With recent trends in sustainability and social responsibility, we are exploring sea space utilization in a new light. In the offshore world, there are ‘cities’ in operation for decades. Habitable compounds in remote and harsh environments supporting a small population to drill, produce and support oil and gas operations. There is a strong track record for this technology having been developed, tested and proven for the past 50 years. There is potential for this suite of solutions to be repurposed as urban solutions – when others have become familiar with our technology, gained confidence and knowledge to the level we have become accustomed to in the past 5 decades.

|

| 1530 to 1540 | Closing |

| 1540 to 1630 | Networking Tea Break and End of Seminar |

Fee

FREE for SIT STUDENT (upon presentation of student ID)

$60 for NON-MEMBER

$30 for MEMBER

$10 for NON-SIT STUDENT

Payment Mode

Cash: Payable at the registration desk

Cheque: Payable to “Society of FLOATING SOLUTIONS (Singapore)”

Registration

Please register HERE.

PDU

Qualified for 4 PDUs by PEB

Contact Persons

Dr. TAY Zhi Yung

Email: zhiyung.tay@singaporetech.edu.sg

Tel: +65 6592 1944 (O), +65 9876 0496 (HP)

Venue

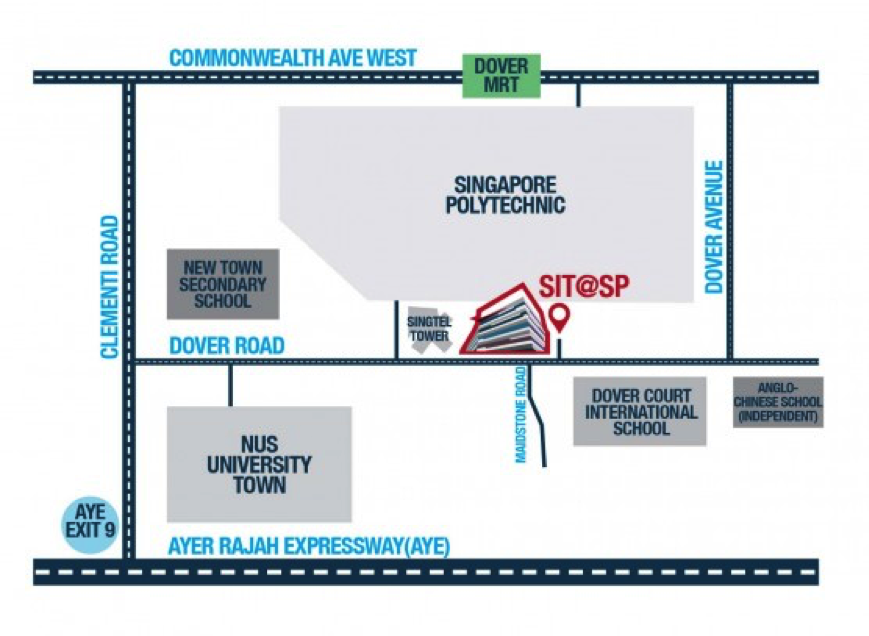

SIT@SP, LT5B, 510 Dover Road, Singapore 139660

DIRECTIONS TO SIT@SP

The nearest MRT station serving SIT@SP will be Dover MRT. To get to the SIT@SP building from Dover MRT, you will have to walk through the Singapore Polytechnic campus.

BY PUBLIC TRANSPORT

The two bus stops directly serving SIT@SP are along Dover Road. They are Bus Stop No.19061 and Bus Stop No. 19069. Buses that stop at 19061 and 19069 are Bus 33 and Bus 196.

Bus 33 – The nearest MRT stations that Bus 33 can be boarded from are Kent Ridge MRT (CC24), Redhill MRT(EW18) and Outram Park MRT(EW16/NE3/TE17).

Bus 196 – The nearest MRT stations that Bus 196 can be boarded from are Clementi Interchange/MRT(EW23) and Buona Vista MRT(EW21/CC22).

BY PRIVATE TRANSPORT

The most direct access to the building is by the Dover Road entrance.

If you are taking a taxi

- Do let the driver know that the SIT@SP building is next to the Singtel Tower at Dover Road. Enter via Gate 1.

If you are driving

- From Ayer Rajah Expressway Heading in the direction of Tuas, take Exit 9 (Clementi Road) and turn right into Clementi Road. Turn right into Dover Road and the SIT@SP building will soon be on your left.

- From Commonwealth Avenue Go in the direction of Clementi, turn left into Dover Ave (right before Singapore Polytechnic). At the end of Dover Ave, turn right into Dover Road and the SIT@SP Building will soon be on your right.

Click here for PDF version of event