SHIPS ARE FLOATING STRUCTURES

Floating structures give the impression that ships are something else. Thousands of years ago ships are called rafts. Rafts are made of reeds, branches, bamboos, in fact anything that give the structure the buoyancy to float. Rafts were replaced by boats made from dug-out tree trunk. The bigger the dug out volume, the greater the buoyancy . These rafts usually depended on sails, current, wind and paddle or oars. Recently a group of Filipino completed a journey 0f 1000 km in a ‘balangay’ to Xiamen that retraces the route of a Filipino Sultan. A ‘balangay’is a type of wooden vessel used in the region as far back as 320 AD.

Two hundred years ago industrialisation saw ships being built to carry raw materials and finished products and passengers. The ships are built of wood followed by iron and then steel. The ships were at first powered by sails then steam reciprocating engines which hastened the progress of ship building. In 1760 Lloyds register of shipping was established in London. The intention was to protect the people and the cargo from the sea. Two hundred years later we are trying to protect the sea from cargo and people on board. The steam engine progressed to steam turbine and finally to diesel engines. In the last two hundred years technology change the ship size, type and shape. Material used and method of construction facilitated by modern welding replaced riveting. The FSO/FPSO render ships to become offshore floating structures in the oceans.

THE Offshore Industry started in the 1950s in the Gulf of Mexico. Oil exploration / production on land migrate offshore, bringing along the platform technology . The fixed platform evolve into jack-ups to give exploration flexibility. As exploration/production move to deeper waters semi-submersibles were used.Mankind’s perpetual seeking of efficiency led to the consideration of employing offshore and ship technology in offshore structures. We could build all kinds of offshore structures from simple landing platform to structures housing nuclear power plants. We have converted large old tankers to floating docks. The main consideration is safety.

The Arctic has 13 percent of the world’s oil reserve an one third of the gas reserve. After losing billion 7 dollars on the Arctic gas project , Shell decided to pull out of the Arctic. The reason is Shell’s plea to focus on resolving the carbon emission issues was not effective in the participation in the universal programme. It paints a picture of lack of interest. For this reason Shell will use the money for the propagation of Shell’s green policy. The Arctic is still the highest priority for the US. The US reckoned that Arctic may be ice-free as early as 2030. But the US has only one heavy ice breaker in the Arctic, compared to Canada and Russia which have dozens. Ice breakers are also floating structures but have to resolve the problem of having lifeboats that work on ice and in water.

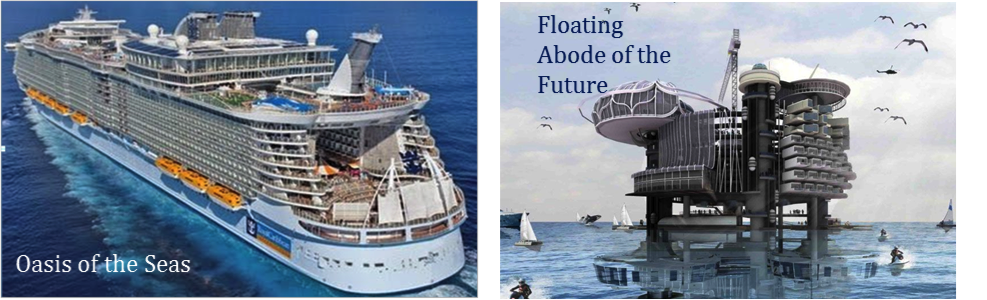

For the ambitious, floating cities, are on the drawing boards. This is not new. In Brunei, I saw a floating cities on stilts. If aircraft carriers can be deployed far away from land so can other offshore structures, like hospitals. Mooring issues will have to be resolved. Tsunami is the known unknown.

19 MAY 2018

Charles Foo

Charles Foo retired at end 2016 after working in the O & M industry for 57 years. He has been Lloyds register senior principal surveyor & Chief Rep for China, the MD (special projects) of Keppel Offshore & Marine and is an Extra First Class Engineer (1972)