Applying VLFS for Shipyard Operations

A paper presented at EASEC14 on 6th January 2016 at Ho Chi Ming City

Lim Soon Heng, BE, PE, FIMarEST

Managing Director, EMAS Consultants LLP

INTRODUCTION

Very large floating platforms provide an opportunity to radically change the way we build, convert or repair ships. The present way of building, converting and repairing ships requires extensive areas of seafront land. This present method is also unable to respond to the rapid changes in business and political environments. Many shipyard owners in UK, Japan and more recently in China had to write off hundreds of millions of dollars in the balance sheet because docks in the ground and berths by the sea were not assets, which their owners could sell or take way to another location when the market turned against them. To compound their woes, millions more were spent demolishing these structures to restore the site they lease.

Shipyards are capital-intensive investments. Management owes it to shareholders to look into ways to minimise their risk exposure, more so if that investment is in a foreign country. Dubai Drydocks World was badly burnt when they had to do a fire sale of the shipyards they acquired in Indonesia and in process allegedly lost hundreds of millions of dollars.

On another level, shipyards compete with other industries for land and waterfront. It behoves state planners to think out of the box and ask themselves does shipyard necessarily be on land.

The general reaction to the concept of floating shipyards is “Is it possible? Wouldn’t it be too costly?” This paper will address this and other issues.

ROOM FOR NEW SHIPYARDS

In the current depressed market, it is natural to ask if there is room for new shipyards. We believe so. We expect seaborne cargo across the Pacific Ocean to expand with the US shift to “pivot” towards Asia and the heralding of the Trans Pacific Partnership (TTP). The Pacific Basin is home to three of the world’s largest economies, US, China and Japan.

China, Korea and Japan currently have 90% of the world’s orders for new ships. However all three countries are in the throes of economic and demographic changes. In the course of this decade, they will see many shipyard closures in addition to those already dying. History will repeat itself and the world will see new shipbuilding centres emerge to replace the current three leaders, as it did in the 1960s. We expect India, Vietnam, Philippines and Indonesia to be among those eager to be in the big league.

LESSONS LEARNT

What lesson can new investors learn from the failures of shipyards in these countries? It is this: Ploughing hundreds of millions into docks and wharves in an industry that competes globally, that is cyclical, that each cycle may be as long as ten years and that is dependent on cheap labour seems like a recipe for disaster. What can one do to mitigate this? For a start, be nimble enough to move with demand and supply. Docks in the ground and piers on the shore lock a business permanently in time and space. The business environment is dynamic so too must the assets in that business. Those assets must be able to respond to those dynamics. This is possible by building a shipyard on a floating platform.

The business reasons aside, can a platform, as large as necessary for a shipyard (say 50 to 100 hectares in area), float safely in the sea? The concept sounds outrageous, but so does the idea, a hundred years ago, of flying across continents. Scepticism too, surrounded the first high rise concrete building erected in 1903 (same year as the Wright Brothers’ epoch-making flight). Engineers expected it to collapse under its own weight. It did not. In the following pages, we hope to dispel such scepticism.

LEARNING FROM THE OFFSHORE RIG INDUSTRY

The advances in just the last three decades of offshore rig construction are inspiring. Today thousands of men work round the clock in some of the most inhospitable oceans on this planet on platforms that were inconceivable just a generation ago. These structures provide lessons for many other applications elsewhere.

Many assets that are traditionally built on terra firma may be better located in coastal waters. They were built on land not because that was the best place to be but because the technology was not there to consider the alternative of having them on floating platforms. Now with three decades of designing and building floating offshore structures, we know enough to consider the option of spaces in the sea for structures, particularly if they function more optimally in water.

LARGE PLATE LIKE FLOATING PLATFORMS

As a platform for shipyard processes, the float has to have a large surface area. However, for economy, the overall depth should be as small as possible consistent with live load requirements.

The deck payloads that it has to support are large (in the order of hundreds of tons) and not always in the same spot. In addition to the horizontal loads due to waves, currents and winds, it has to resist the impact of the mass of vessels (some in the order of tens of thousands of tons). Moorings need to secure them in the event of typhoons and tsunamis. These are the challenges that need to be addressed in its design.

Fortunately, the research and development that has taken place, the experience gained in their construction, and use of floaters in the offshore oil and gas industry provide many tools that may apply to the design of plate like platforms. Independently several other research groups in universities and commercial laboratories have added to these tool kits with their investigation of the hydroelastic behaviour of such flat platforms.

Examples of large floating surfaces that are in use, or on trial, include the following:

- The one hectare Float@ Marina Bay in Singapore (steel)

- The (trial) 1000 metre long runway in Tokyo (steel)

- The 700 feet x 100 feet, container terminal port in Valdez, Alaska (concrete)

- The 2310 metres x 23 metres floating section of the Evergreen Point Bridge (concrete)

Perhaps the floating structure that best resembles our concept of floating shipyards is the container terminal at Valdez, Alaska. It was fabricated in two sections, 1600 miles away in Tacoma, WA. See Fig. 1. The two sections were post tensioned together at site. Each section has 16 watertight compartments. As this was a container port for discharging cargoes, it had a deep draft (55 feet). The float was designed to take the horizontal impact of a fully loaded berthing container ship. Valdez is in a region of Alaska that experienced an earthquake and tsunami March 28, 1964. When this port was built in 1982, it is reasonable to assume that this was taken into consideration. The port, which handles vessels up to 50,000 dwt., is equipped with 12 nos. 50-ton bollards testifying to prevailing heavy weather.

THE SINGAPORE SHIPYARD SCENE

A short account on the Singapore shipyard situation is included to put this paper in context.

Singapore’s west coast is dotted with shipyards, all of which are built on reclaimed land and most of them busting their 30-year lease, small in size but with no room to expand. The lessees are pressing the landlord for a solution. The old solution of creating land by reclamation has become far too costly, as all shallow water areas have been reclaimed. Besides, it would take too long to satisfy immediate needs as newly reclaimed land takes five to ten years to consolidate before any civil works can begin.

The competition for seafront land has driven up its rental rates, which are already among the highest in Asia. With local shipyards facing stiff competition from China, Indonesia, Vietnam and India, their margins have thinned and their ability to pay more for land rent is diminishing. There are two options for those yards whose lease has run out. The first is liquidate whatever assets can be liquidated and retire from the industry altogether. The second is to relocate their business in countries eager to attract such foreign direct investments. With second option, there are two sub-options: (a) to build a shipyard on waterfront land in the host country or (b) to negotiate with the host country for mooring rights for a floating platform and the license to operate a shipyard on it. With (b) the investor builds and owns the platform and builds his shipyard on it.

FLOATING SHIPYARD

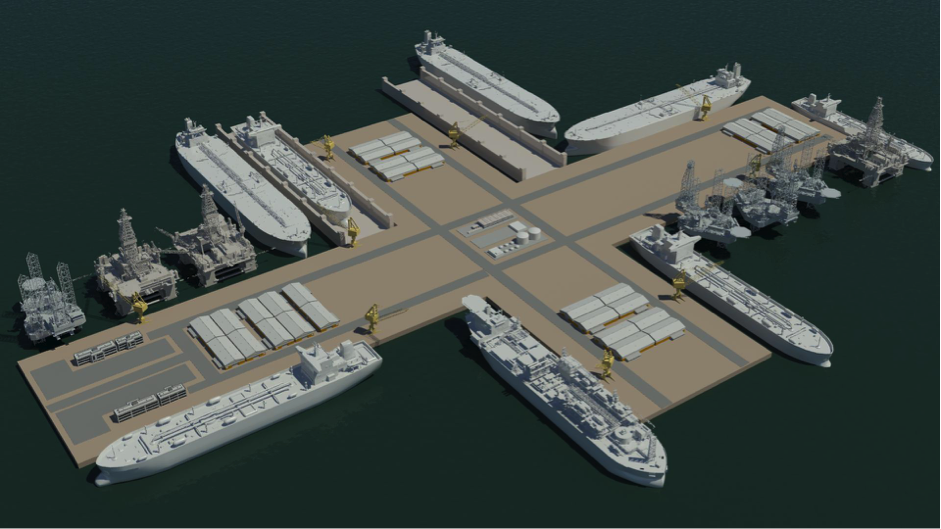

Fig. 2 illustrates a concept of a floating 35-hectare platform that may be suitable for ship and offshore rig building, conversion or repair. The long axis is 1200 metres in length and the short axis, 750 metres. The width of each arm is 200 metres. The periphery is 4000 metres long.

The depth of the float is subject to deck loading, and stability analysis. Although the deck is on a horizontal plane, the depth of the component modules may vary across its footprint being deeper where more buoyancy it is needed. The amount of seawater in the ballast tanks beneath the deck

may be adjusted to prevent excessive build-up of static stresses. As a first cut, for a preliminary assessment, one may assume 5 metres (3 metres draft and 2 metres freeboard).

Rain falling on the impervious deck drains into the tanks below the deck. In the tropics, as much as 700,000 cubic metres of rain annually may fall on the deck. If 70% is harvested, the facility could be self-sufficient in water. Electrical power generated on-board is supplemented by harvesting the energy of wind with vertical axis wind turbines above deck and underwater current turbines below it.

The 4000-metre periphery is fitted with fenders and bollards for berthing ships including VLCCs and offshore rigs. It has two floating docks (each 70 m x 380 m) berthed parallel as shown or if space allow at right angles to the side of the float. As a floating dock requires a depth of more than 15 metres when fully submerged, the location of the platform should take this to consideration in order to avoid having to dredge and maintain a pit to accommodate the dock.

On its deck, straight roads facilitate the movement of heavy duty multiple axle transporters. The ratio of berth length to land surface is 114 m/ha. Keppel Tuas Shipyard in Singapore, see Fig. 3, by comparison has less than 60 m/ha. It is forced to double bank vessels. The extensive berth capacity arises not from the construction of any piers or jetties.

They are available as part of the platform, requiring no additional structures. This is a valuable feature. A 4000-metre berth in a typical onshore shipyard would cost about $150 to 200 million to construct depending on soil condition and its designed depth. Fig. 4 illustrates the complexity of the design and construction of a conventional quayside berth. The hull of floating platform, which serves the same function as such quays or finger piers require significantly less resources to construct. The construction time is shorter and the risk due to difficult ground conditions non-existent.

The platform may be moored in water depths from 15 to 20 metres without cost impact on its manufacturing cost. The construction cost of a land-based quay/berth, on the other hand, varies exponentially with depth. Breakwater is not necessary if the significant wave height is less than 4 metres.

Deep-water berth is a key selling point for ship repair yards as the depth quite often limits the range of ships it can service. Wide-bodied rigs, which cannot be accommodated in any graving or floating docks, may be serviced by lifting it above water with a “floating barge” such as illustrated in Fig. 5. This procedure is not possible if the quayside water depth is less than 12 metres, which in effect rules out many shore-based competitors. Ships requiring emergency repairs because of accidents are often unable to discharge their cargo to reduce their draft. In such cases, they are obliged to seek shipyards with deep-water berths. Ships with fine hulls generally have deep light load draft. They need to use shipyards with deep-water berths.

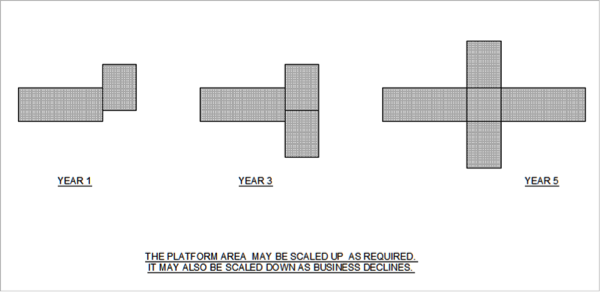

The 35-hectare float is not monolithic but comprises a number of rectangular modules linked together. It is assembled with 100 m x 50 m modules or with modules of same aspect ratio. Fig. 6 shows how the shipyard may be expanded as the business improves. Conversely, if business declines, parts of the platform may be detached and relocated to a better market. The platform parts may be recycled for other uses such as for the erection of a resort hotel, a condominium complex, a college campus, a warehouse. With such a wide range of possible re-use, it may be even be likely that an offer may be received that exceeds its book value.

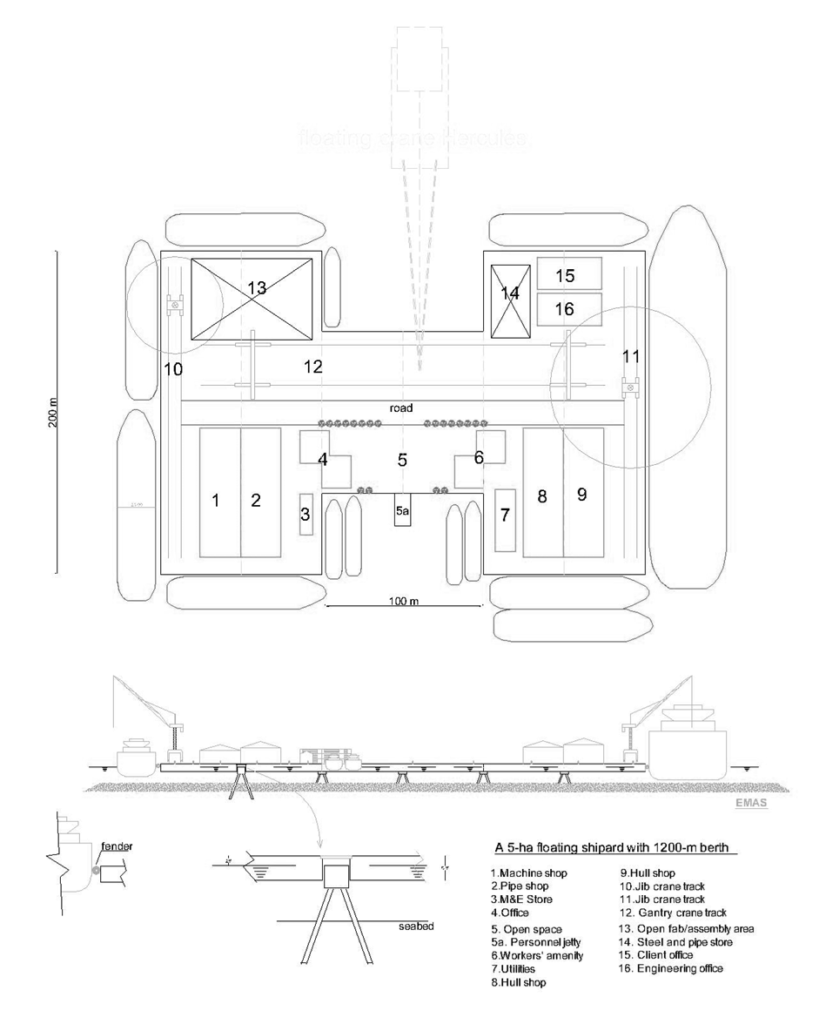

Fig. 7 illustrates the cross section of a smaller 5-hectare shipyard with an H-shape footprint. It shows a possible mooring arrangement. The layout is indicative of the type of shipyard equipment that may be erected on board, including gantry crane and quayside jib cranes. The floating crane shown to scale, shows how heavy objects may loaded or offloaded from the platform. The rectilinear shape permits a very efficient layout for a wide range of workshop and uncovered fabrication area. It has 240 metres of quay space per hectare of deck space. Such a layout is ideal for shipyards servicing the osv (offshore support vessel) sector. The illustration shows it can also accommodate larger vessels up to 200 metres.

The module-to-module connection is an important design detail. A rigid connection would be preferred if the structure is able to take the bending moment that may arise due to deck loading and waves, which of course depends on the width and depth of the adjacent modules. However, consideration may be given to pin-joined floating bridges, as a means of avoiding large bending moments due to wave action. The bridges should be strategically placed to ensure they do not cause inconvenience to production activities.

The ease to expand the platform in response to market demand for its services cannot be overstated. On land, this is not always possible. To buy and hold adjacent land in anticipation of future expansion is a costly option and in some countries not legally allowed as it is deemed as hoarding and hence morally unacceptable. To have the option to add more platforms, but only when the market justifies it, reduces business risk and cost of borrowing. The fact that some or all the modules of the platform may be detached and sold if necessary further reduces that risk.

Some shipyard managers express concerns that certain shipyard procedures may not be possible on a floating platform. The questions they ask include will precision work (machining, honing, grinding) be possible on a floating platform? Is it safe to use a quayside jib crane on a platform? Is it safe to load and unload very heavy (500 tons or more) objects on and off a floating platform? Can ships be launched safely from the platform? These are valid questions. They relate to a perception of wave or wind induced motion. If the platform was the size of a tennis court, rolling motion could be a problem but not when it has a surface area of more than 20,000 sq. metres. The amplitude and frequency of the platform can be estimated scientifically given the dimension and mass of the platform and the applied force. It is also important to know the natural frequency of the platform and that too can be calculated. Sensitive machines may be installed with dampers or vibration isolators on foundations with a high mass.

Any shift in the loads on the deck or the loads on cranes mounted on the deck or workshops will naturally shift the combined centre of gravity of the platform and its load. However, a 20,000 sq. metre platform for example would have a mass of at least 40,000 tons. A change in position of a load of 500 tons over say 10 meters will not destabilise the platform. If needed, the angle of heel can be estimated analytically. If the tilting is intolerable, it can always be corrected by adjusting the ballast water.

Launching newbuildings1

Launching newbuildings from a shore quayside by skidding over to a floating transporter or a floating dock is common in many shipyards.

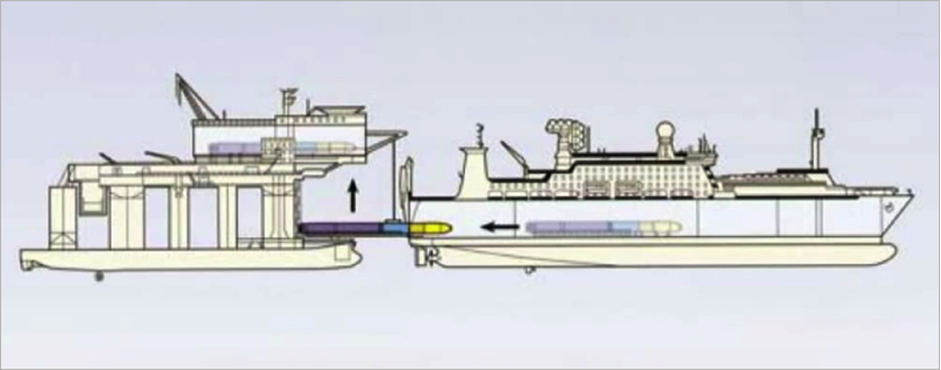

The skidding over of a rocket from a ship (Sea Launch Commander) to a launch pad (Odyssey) as shown schematically in Fig. 8, proves that skidding a load from one floating structure to another is not impossible. Similarly a newbuilding may be transferred (preferably in the longitudinal direction of the platform for stability) across to a floating dock. The floating dock is then submerged, causing the newbuilding to float. Of course, such a procedure should be analysed to ensure that any bending moment induced on the platform can be mitigated or is within the safe limits of the float.

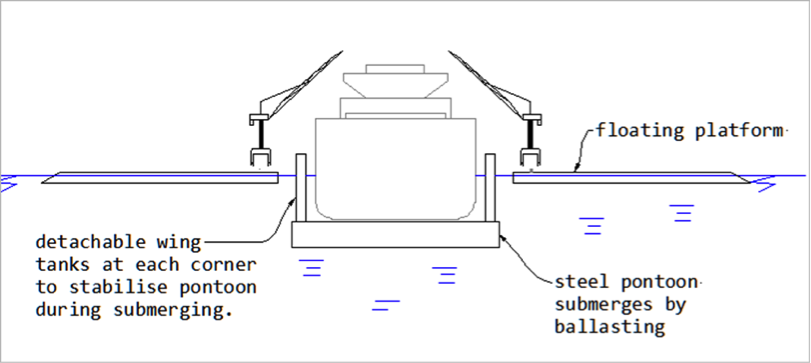

An alternative method of launching without the use of floating dock may be investigated. One procedure may be to design the float where the newbuilding assembly area is provided by a steel pontoon, which lies within the footprint of the floating platform. The pontoon is fitted with ballast pumps and may be ballasted to submerge it independently of the rest of the platform and to the extent necessary to float the new vessel. See Fig. 9. To maintain stability when the pontoon deck submerges below the water line, detachable wing tanks may be fixed to maintain the metacentre above the centre of gravity. When not in use the wing tanks may be removed so as not to obstruct activities.

Conversely, a ship may be floated over the pontoon and lifted by deballasting its tanks (with wing tanks attached) until the deck of the pontoon is flush with the deck of the rest of the platform. This procedure has the same effect as a ship lift (or syncro lift) in that it ends up with the ship at the general level of the work platform except that water buoyancy is used to lift the vessel and to support it rather than winches and piled foundations on land. This is more cost efficient than an equivalent shiplift system as no civil works or costly winches are necessary.

(1This term applies to new ships, fully or partially completed.)

Clustering

A critical mass of shipyards is necessary for the evolution of a network of supporting services that they depend on for efficient production. Shipyards on floating platforms when they relocate from one region to another would be able to regroup easily to a size that will attract third party service and equipment providers.

FLOATING DOCK-FLOATING CRANE SYSTEM

Traditionally ships are built by assembling prefabricated blocks in a graving dock with a goliath crane. We shall refer to this as the GDGC system. The alternative way is to assemble the blocks in a floating dock using a floating crane, hereafter referred to as the FDFC system which practiced extensively by South Korean shipbuilder Daewoo (DSME). We propose this system to be integrated into of our concept of a floating shipyard. Blocks can be prefabricated on the floating platform. A floating crane picks up each block, transports it to the floating dock for assembly. See Fig. 10.

The choice of the FDFC system is based on the following considerations:

- The FDFC system is relocatable. It is easy to relocate the hundreds of millions of dollars’ worth of asset out of harm’s way if the business environment looks threatening.

- Banks consider mobile assets as mortgage more favourably than immovable assets.

- If financially advantageous, separate companies may be set up to own either the floating dock or floating crane or both. It is not meaningful to do likewise for assets that has no value to others except the owner (which it the case for graving docks and goliath cranes).

- It is not easy to liquidate graving docks (including pump house, pumps and dock gate) and the crane runways, when the business environment plummets.

- The construction of a graving dock and the foundation for the goliath crane depends on ground conditions at the construction site, which not infrequently differ from design assumptions based on borehole samples. Unforeseeable or unforeseen ground conditions cause disputes, delays and cost overrun between the employer and contractor.

- Floating cranes lift much heavier loads than goliath cranes.

- Floating cranes can lift a block or module from one shipyard for installation in another, facilitating subcontracting during busy times.

- One floating crane can service several floating docks; one goliath crane can service only one (very occasionally two) dock.

- Floating cranes may be deployed for erection of bridges or the salvation of wrecks, thereby optimising its utilisation. Goliath cranes cannot.

ANALYTICAL TOOLS AND REGULATORY REGIMES

Theoretical models have been developed by leading universities to investigate the hydrodynamic behaviour of large mat (or plate) like floating structures as well their hydro-elastic response to waves, wind and payloads. These are reinforced and verified by experiments in leading hydromechanics laboratories including some of the best in the field such as SINTEF and TU Delft. The mechanism for stability of intact and damaged floating structures are well understood by students of naval architecture and many software have been developed to make the task of analysing these conditions effortless. Designs are regulated by codes or rules of long established and globally recognised classification societies such as Lloyds Register of Shipping, American Bureau of Shipping, Net Norske Veritas, Bureau Veritas, Nippon Kaiji Kyokai.

The comfort and safety of those working at sea are not forgotten. The IMO (International Maritime Organisation), an organisation under the UN Charter ensures that. One of its divisions MARPOL (Marine Pollution) ensures that the sea remains clean and no marine life come to harm by man’s activity in the seas. Compliance to IMO and MARPOL is mandatory for all signatory countries of the Convention.

These tools and regime are all we need to design, test and to verify the performance through physical and numerical models to ensure the safety of large floating platforms for use as shipyards or indeed any other purpose. Classification societies will endorse for a fee, designs that comply with their rules. That endorsement is generally necessary for underwriting and fund raising purpose.

MANUFACTURING THE PLATFORM

The platform may be constructed with shipbuilding steel or with high strength lightweight geopolymer concrete. Both materials will provide at least 50 years of service. Corrosion issues and their mitigation of steel and concrete are well documented and need not be discussed here.

Steel platforms are best manufactured in a shipyard, in a controlled environment and properly coated with paint. The blocks are assembled in a dry dock for ease of launching.

Concrete platform may be manufactured in an open site and launched using launch ways with, if preferred, airbags. After sufficient number of modules have been cast and connected to form a sizeable platform, it is used to cast other modules. To launch the modules the platform is inclined by ballasting its tanks.

Alternatively, if a suitable shallow (4 to 6 metres deep) bay is available, a simple earth cofferdam may be constructed at its entrance to form a temporary polder or dry dock. The enclosed area is dewatered. All modules can be cast inside after suitably preparing the ground. When completed the area is flooded, the cofferdam is removed and the modules towed to site for connecting.

Fig. 11, a screen grab from YouTube, shows the casting of the 352-metre floating quay in Spain in a temporary dock. The quay was towed to Monaco where it was installed.

For mass production, concrete modules (caissons) are best manufactured in a floating dock fitted with an elevating platform from which concrete is poured. To float the module the dock submerges. It is towed out of the dock by winches or tugboats. Fig. 12 is a picture of floating plant employing this system.

DELINKING OWNERSHIP AND MANAGEMENT

The owner of an asset is not always the best person to run it. The best person to use an asset to make a profit may not necessarily have the money to own it. Most large shipyards are state owned or owned by conglomerates with close links to the state. State owned shipyards such as those in Britain (under the state organisation, British Shipbuilders from 1978 to 1987) and in China are notoriously inefficient.

Shipping magnates own ships and charter to others to find cargoes and sail them. However, this business model is uncommon for shipyards understandably, because land-based shipyards with immovable docks and quays are too risky even without the prospect of nationalisation. Many shipyards in China are in financial distress, including new ones like Rong Sheng Shipyard and Nantong Minde Heavy Industries.

The balance sheet of a land-based shipyard is denominated in the currency of its host country. That balance sheet takes a hit when the country’s currency plummets as is happening in Indonesia.

When the entire shipyard is a movable asset like a ship, the risk is lower because if the environment becomes unstainable (because of shortage or high cost of labour as Japanese shipyards are experiencing) he may tow away the facility to a more favourable location. Alternatively, he may auction the floating docks and cranes but hold on to the platform on which he can erect other revenue generating structures.

The separation of management from ownership of a shipyard promotes the emergence of a breed of groups of managers with a global identity (like Sheraton or Marriot in the hotel industry). The marine industry will stand to benefit from teams with a global management expertise, development resources and marketing network. The economy of scale will cut out duplication of research and development, empower procurement negotiations with vendors, enable better use of high-end computers, and provide staff development on a global platform.

SUMMARY AND CONCLUSION

Ships and offshore rigs may be built, repaired or converted with a system comprising floating docks, floating cranes, and floating platforms. The system is superior to a typical land-based shipyard for the following reasons:

- It is a movable facility that may be relocated when necessary.

- Being a movable asset, it may be deployed to a lower cost but higher risk environment where a land-based shipyard would be vulnerable to the vagaries of local and international politics.

- It may be scaled up or down in respond to market demand and supply for its service, thereby reduce its vulnerability to market dynamics.

- The sides of the platform serve as berth spaces, doing away with the need to construct piers and quays. It may be moored in deep waters to preclude dredging and to widen its market base.

- It is better able to survive earthquakes and tsunamis than land-based piers and docks.

- The platform has alternative uses if the investor/owner wishes to exit the business. The investor/owner is not required to demolish civil structures when he returns the land to its owner or sell the land to others.

- It is not subject to risks of unforeseen ground conditions during the construction of graving docks and piers.

- The construction period is shorter and hence the project overhead and financing cost are lower.

- It facilitates the separation of asset ownership and asset management and promotes the emergence of global professional shipyard management teams.

- It provides an ecologically friendly solution than reclaiming land for building a shipyard.

The water front land is premium space for offices, hotels, apartments, gardens and parks. Industrial facilities like shipyards, nuclear power plants, incinerators and warehouses, which are land intensive, unsightly, pollutive or hazardous, should be built offshore. The relocation of industrial assets offshore takes pollution and other health hazards from urban areas. The explosion of a warehouse in Tianjin in October 2015 is a case in point. The destruction of the nuclear plant by tsunami in Fukushima is another. The other benefit is the removal of heavy vehicles associated with such industries during their construction and operation from urban highways and roads. For example, the catastrophe on a highway in Bangkok in 1990 killing 90 people was due to a tanker carrying LPG.

With the technology of building, and mooring them against the forces of nature firmly proven, floating platforms provide an opportunity to consider win-win solutions for state urban planners and industrialists. They are more cost effective in countries where land is expensive. They also provide solutions to keep our urban environment safe and clean.

August 21, 2015.

Singapore.

References

- Hydroelastic analysis of pontoon-type VLFS, A literature survey by E Watanbe, T Utsunomiya and C M Wang.

- Large Floating Structures, edited by C M Wang and B T Wang (published by Springer)

- Floating Concrete Structures, examples from practice, Second Printing 1992, published by VSL International Ltd, Berne Switzerland.

- Marine Structures for the Future, by Torgeir Moan, Norwegian University of Science and Technology.

- An offshore floating nuclear power plant concept, a video on YouTube uploaded by MIT Professor Jacopo Buongiorno.

- Shaping the integrated floating stage at Marina Bay, by Dr Koh Hock Seng and Lim Yoke Beng.

- Industrial waterfront land prices, JTC website (http://www.jtc.gov.sg/industrial-land-and-space/pages/land-for-general-industries.aspx)

- China Finally Overcomes South Korea, a report in Hellenic Shipping News/Shipbuilding 11/03/2013

- One-Third of China Shipyards Face Closure as Orders Slump, report in Bloomberg, July 5, 2013.

- Dubai Drydocks World Makes Offer for Labroy Marine, a report in Rigzone October 29, 2007

- Drydocks World ties up with Asian group, a report in Financial Times July 27, 2012.

- Govan: A shipbuilding history, a report by BBC, November 5, 2013.

- The London Britannia Airport, a proposal by Gensler in partnership with TESTRAD (The Thames Estuary Research and Development Company.

- Floating Concrete Container Terminal at Valdez, Alaska, ABAM Engineers Inc, FederalWay, Washington.

- Evergreen Floating Bridge, by Historic American Engineering Record (HAER No. WA-201).

- Loading of the clipper “City of Adelaide” on to mv Palanpur videos and 3D simulations, uploaded on Youtube by Combi-Lift.

- Construction of floating pier in Monaco, Quai Rainier III, video on YouTube.

- Monaco pier extension, by Capt Piet Sinke (SMIT).

- No more land? Build floating real estate, an article in Today Newspaper January 14, 2015